VALVE BODY TEST MACHINE

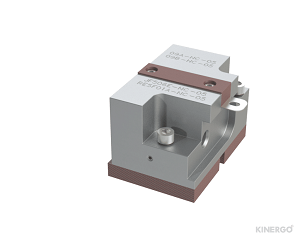

VBTM-K | GT 01.100

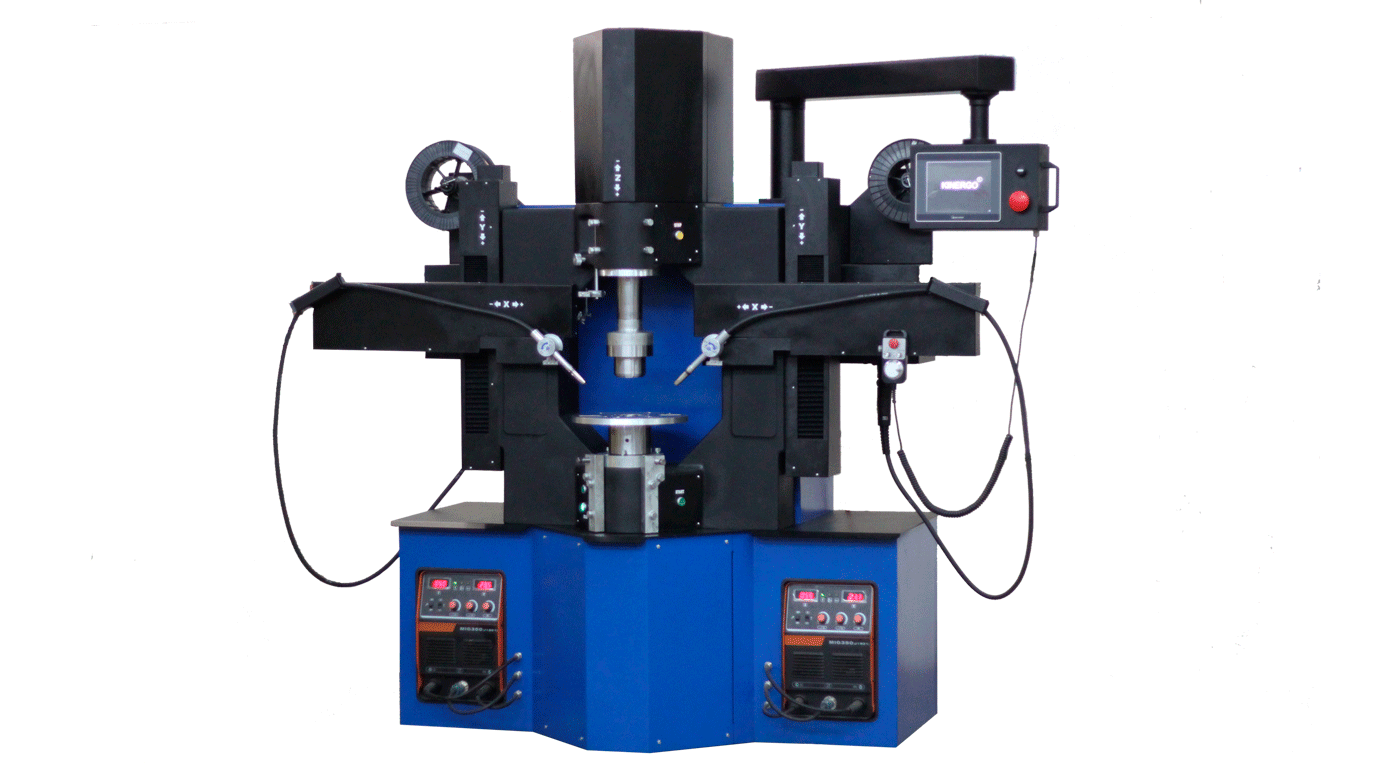

The VALVE BODY TEST MACHINE is manufactured for testing and diagnostics of valve bodies of automatic transmissions.

This machine imitates the operation of an electronic control unit of an automatic transmission by means of an electronic controller and supplies voltage to the solenoids of the valve body, according to pre-written gearshift algorithms. Then the output pressure readings are taken from each channel, graphs are formed showing the deviation of the pressure of the tested valve bodies from the reference (valve bodies).

The testing process is carried out with ATF working fluid heated to operating temperatures and located at various inlet pressures. This eliminates the error that occurs when the viscosity of ATF changes at different temperatures.

Graphs with reference tests of the new valve bodies are pre loaded into the software.

The sequence of work:

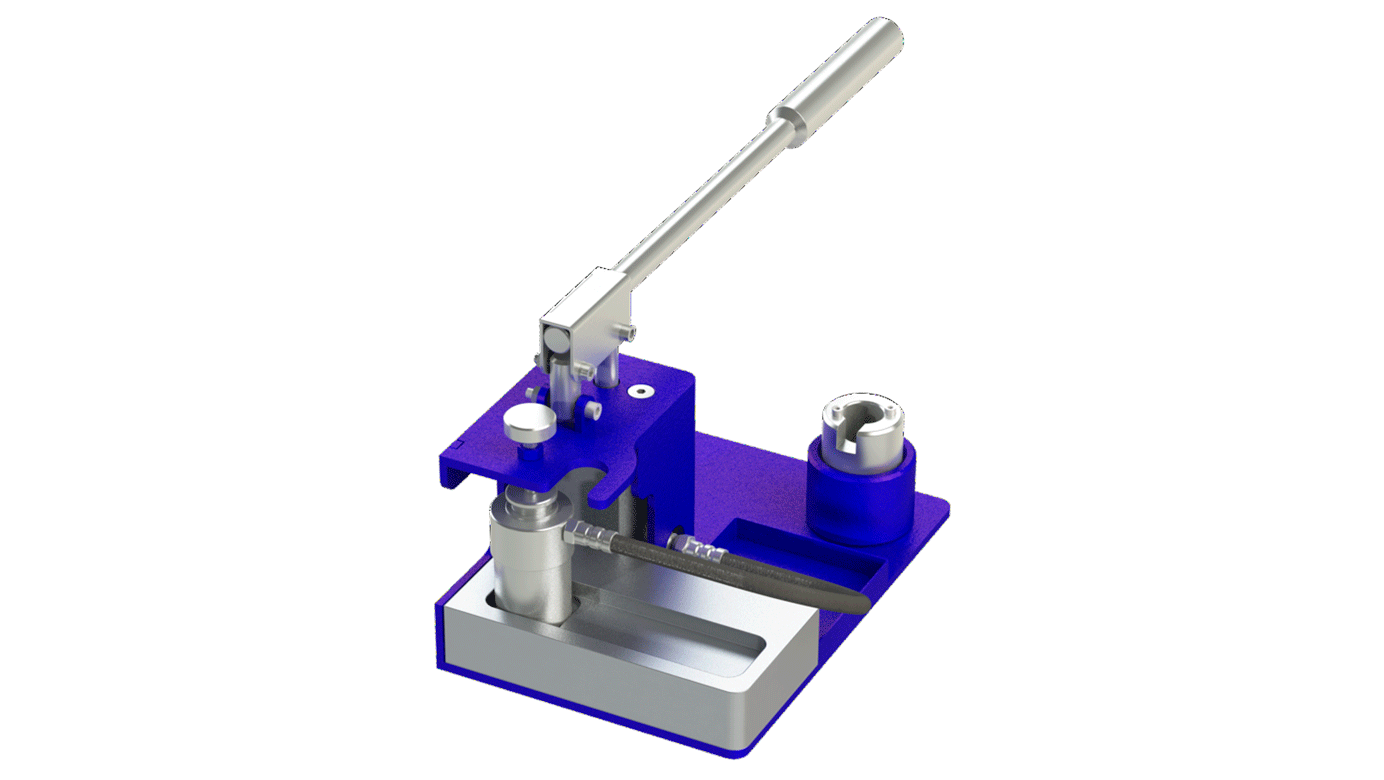

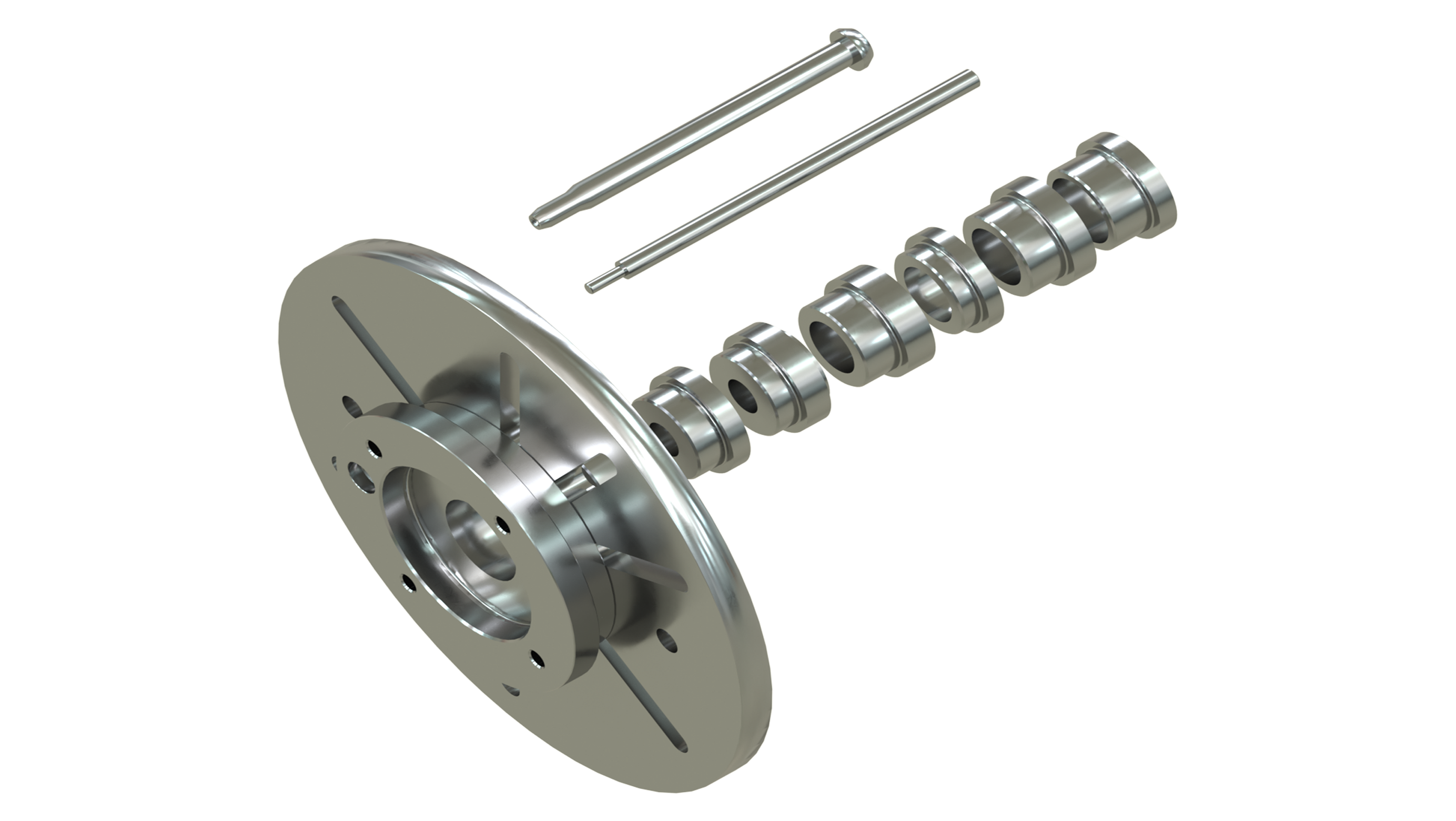

1. The valve body is installed on the adapter plate, sensors are connected to the output channels and the operator starts the first test. 2. The set of tests is repeated for different values of the inlet pressure. 3. After the test completion, a graph with the test result is displayed on the screen.

The VBTM-K valve body test machine gives out a certain algorithm that the valve body should perform. At the same time, the VBTM-K valve body test machine can set various operating modes of the valve body for a full check of its reliability and fault tolerance. Pressure sensors are installed on the output oil lines coming from the valve body, which take readings at each unit of time.